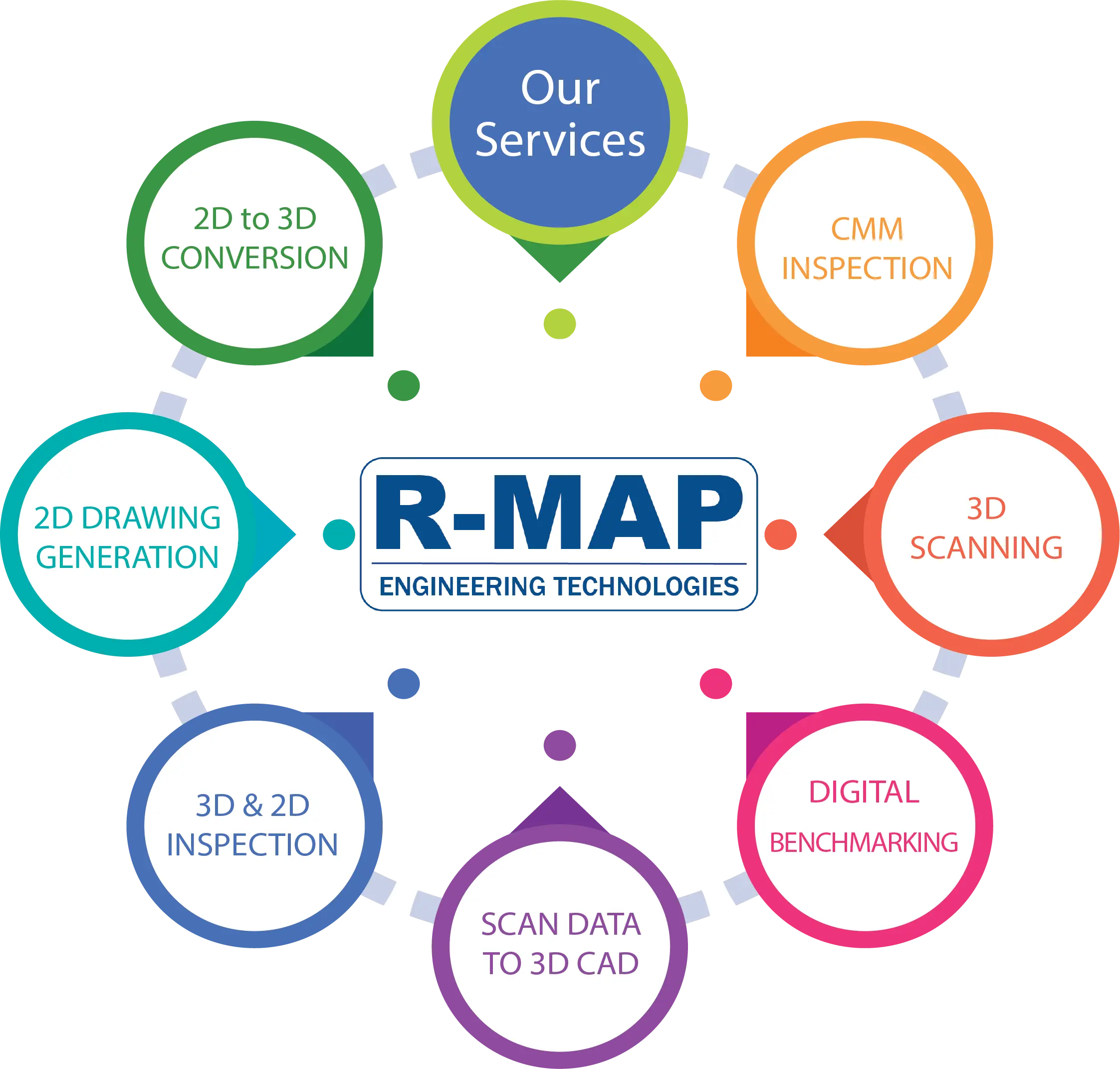

Our Services

3D scanning, Reverse Engineering and CMM Inspection. Availing Flagship and up-to-date scanning hardware and software.

(+91) 86006 01444

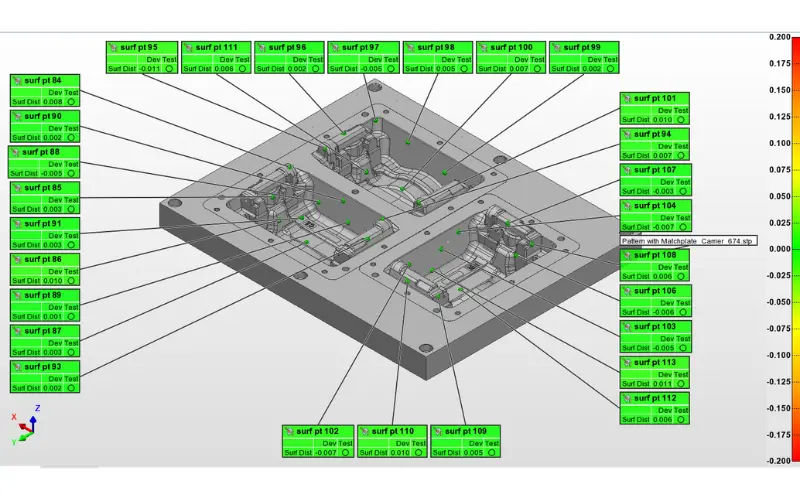

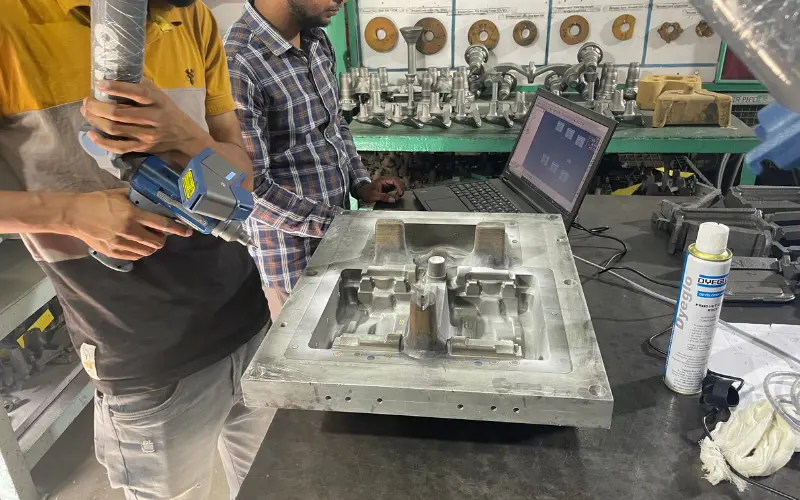

CMM INSPECTION

You can capture every dimension of a complex part, tool, die, mould, jig, and fixture by simply touching it with the help of Portable CMM. It works in labs, shop floors, or in the field at extreme temp. conditions., It gives great flexibility in 3D measurement of all types of complex geometry Large parts inspection up to 4 meters

Application –

- Die

- Press Parts

- Machined Component

- Mould

- Jig & Fixture

- Pattern Inspection

Sub Heading

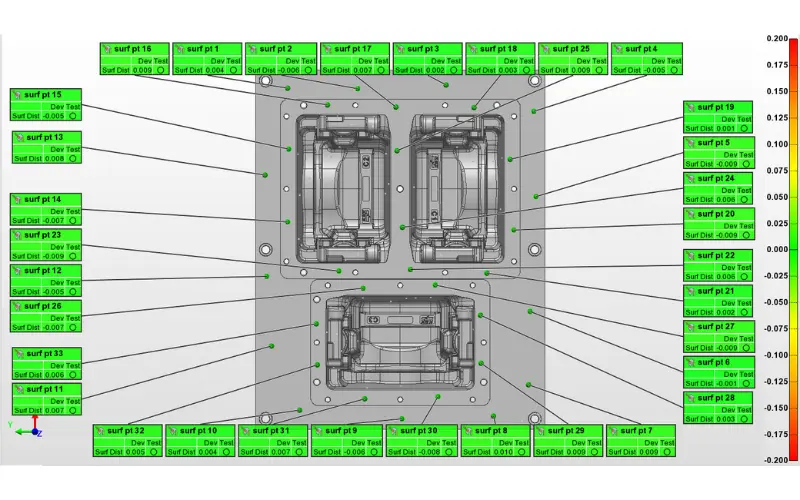

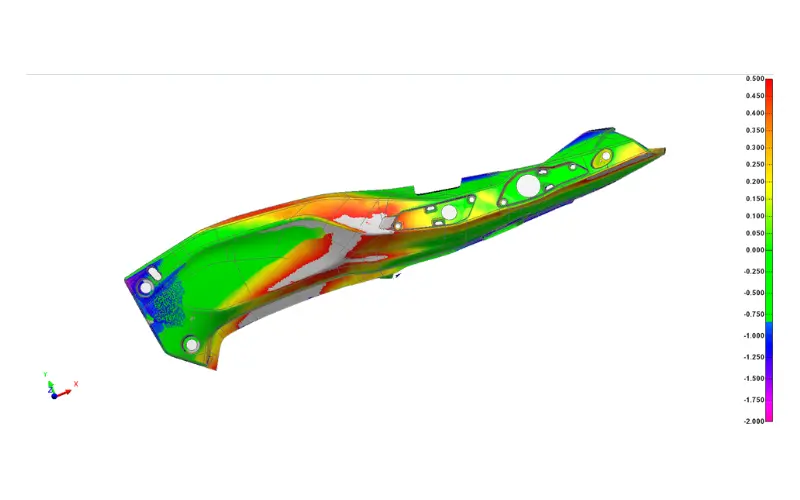

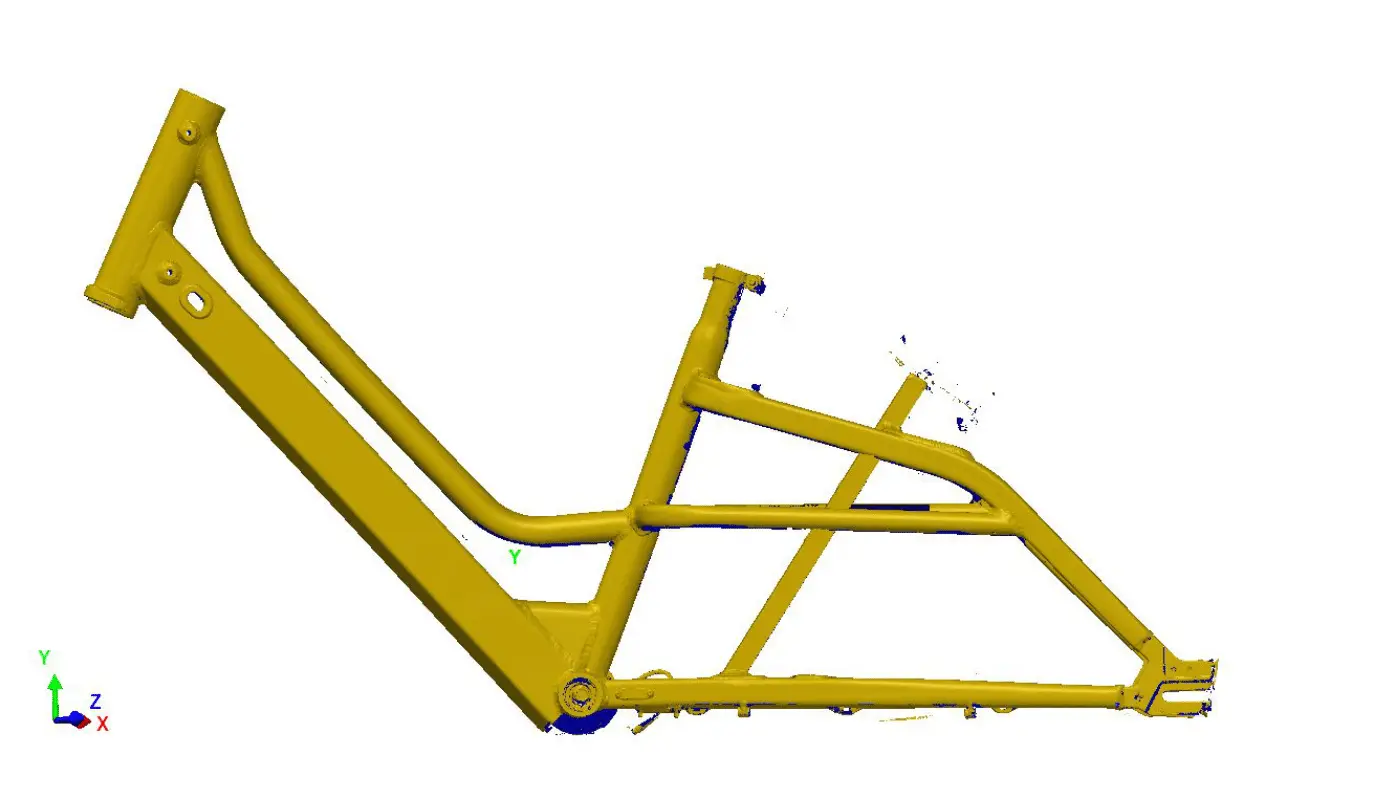

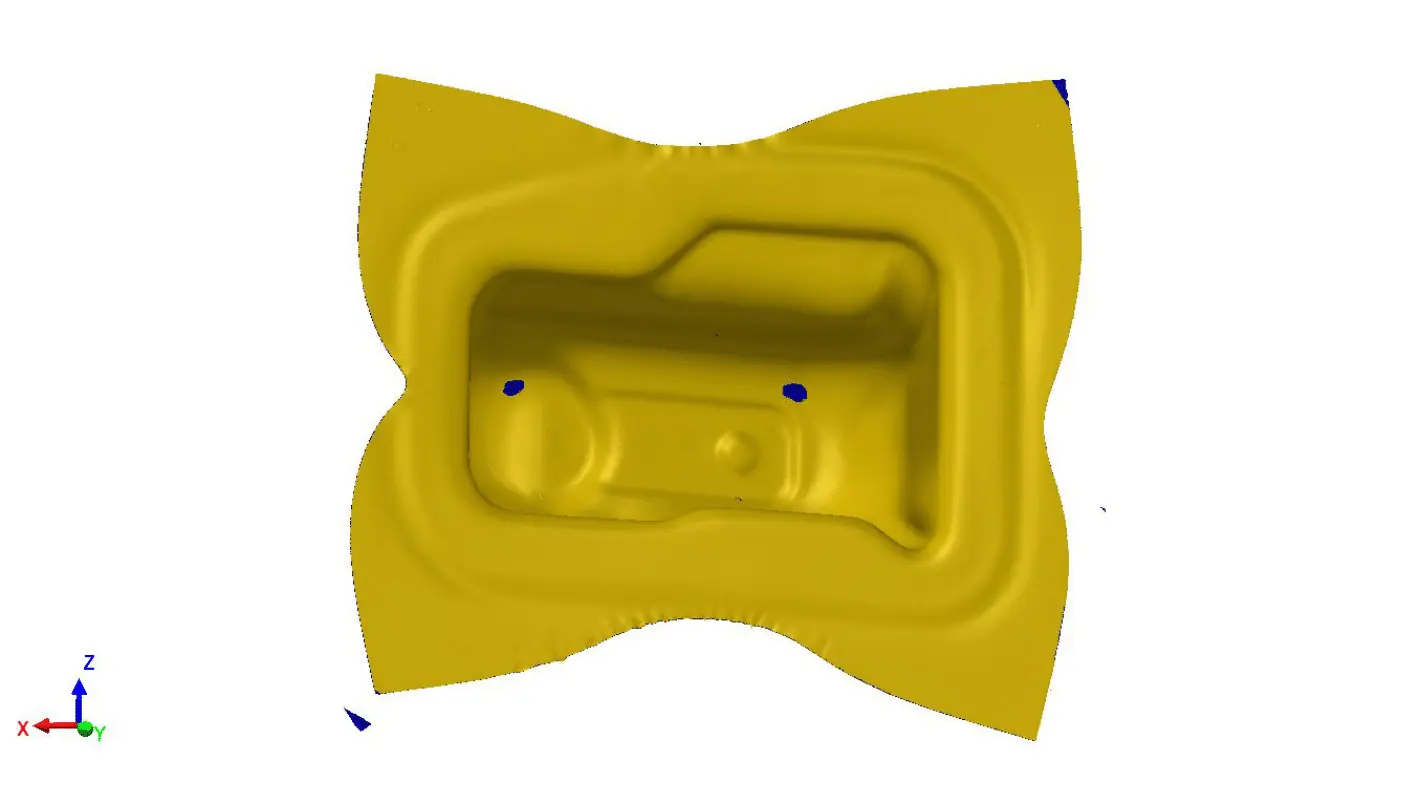

3D SCANNING

Sometimes in complex parts one can not use contact type measurement then non-contact type 3D scanning technology comes in, with great speed and accuracy FARO Scan arm gives freedom of both CMM inspection and 3D scanning.

Application –

- Injection moulded sample parts inspection

- Reeform shaped press parts plastic parts inspection by comparing it with CAD models

- Point cloud data collection

- Input for reverse engineering application

- Data input for 3D printing

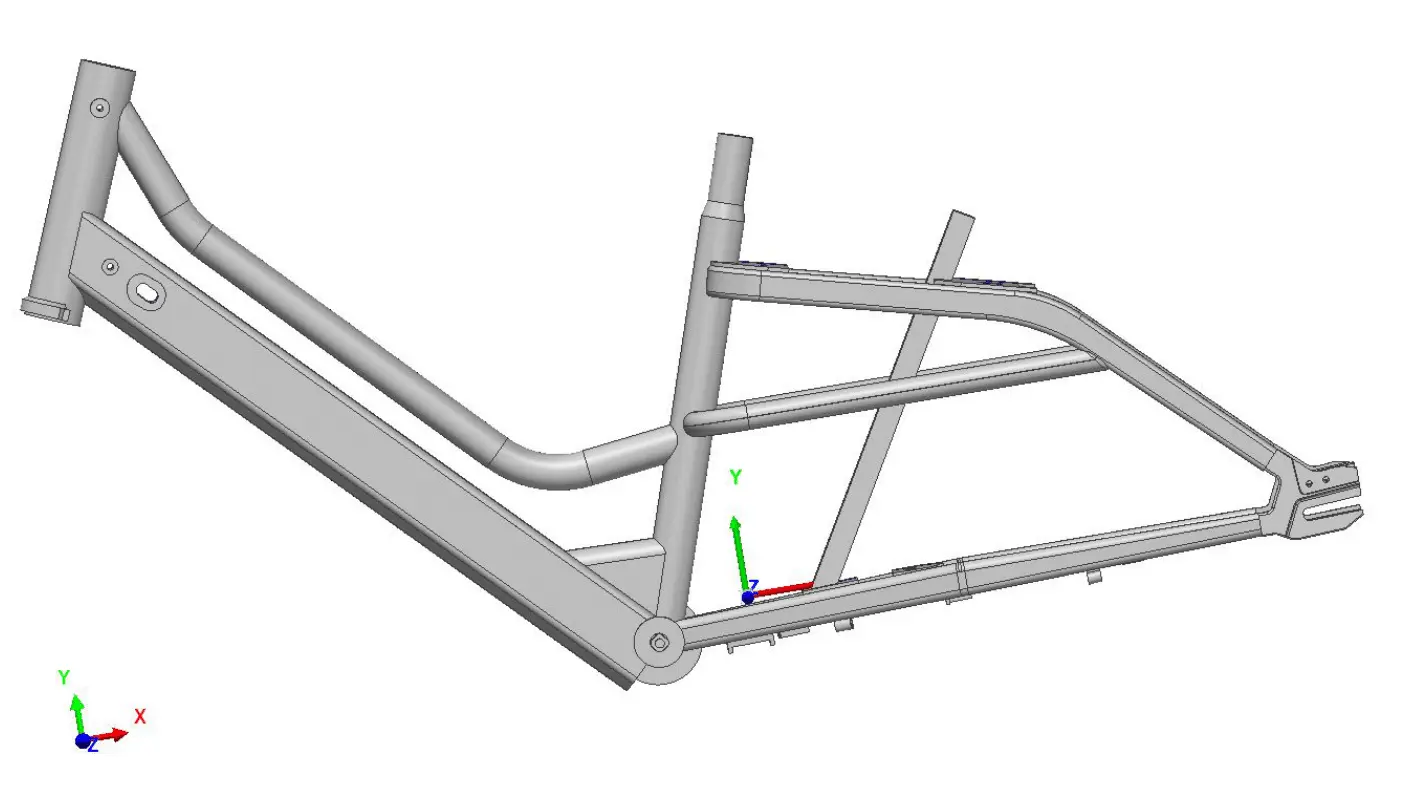

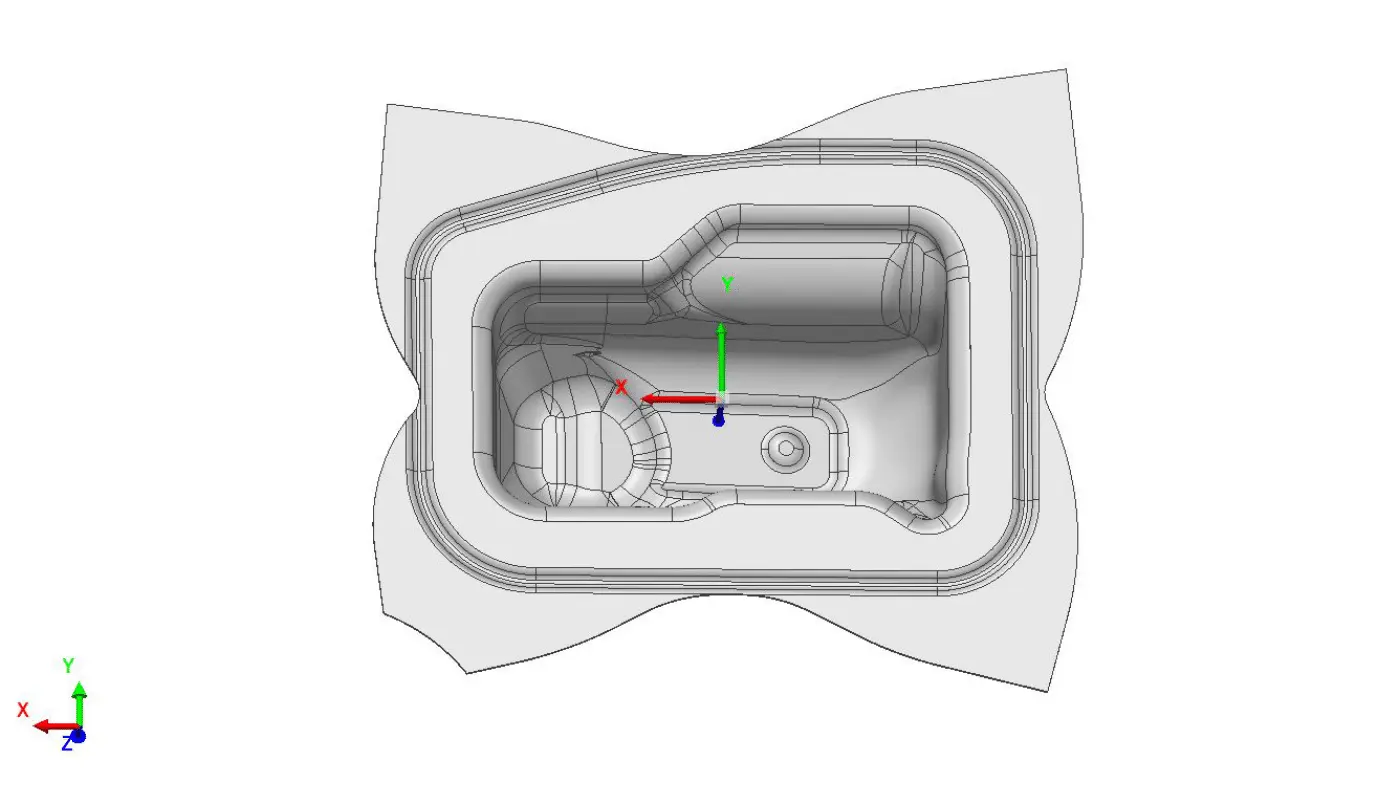

REVERSE ENGINEERING

Developing CAD data from physical components, The purpose of reverse engineering is to recreate the object or to enhance existing object performance It is usually used to create benchmarking, exploring existing design, reconstructing outdated product, creating CAD data of a breakdown part, reduce time to market.

Other Projects

Text

Description

Text

Description

Text

Description

Contact Us

Phone

+91 8600601444